What to prepare before opening a flour mill factory please?

What to prepare before opening a flour mill

I. Market research

1. First, we need to conduct a market survey. Understand what kind of flour is currently needed in the local and other surrounding markets, and then determine which group or region our flour is sold to, whether to produce high-end flour or mid-range flour, and what requirements the gluten content, moisture, and ash content need to meet, so as to have a clear idea and provide a basis for the future flour processing technology and equipment selection.

2. Source of raw grain

Through market research, we can understand the nature of raw grains in the local and surrounding areas (such as whether wheat is hard wheat or soft wheat) and prices, and then compare them with the prices of imported raw grains, and choose raw grains that are suitable for the sales area. To reduce the transportation cost of raw grains.

II. Factory site selection

In principle, the site selection of the factory area should be selected in a place with convenient transportation and convenient access to raw grains and finished products. Areas such as dust, insect pests, chemicals, and radioactive pollution should be avoided. At the same time, understand the local government's policies and regulations on land acquisition and environmental protection. So as to choose a factory site that suits you.

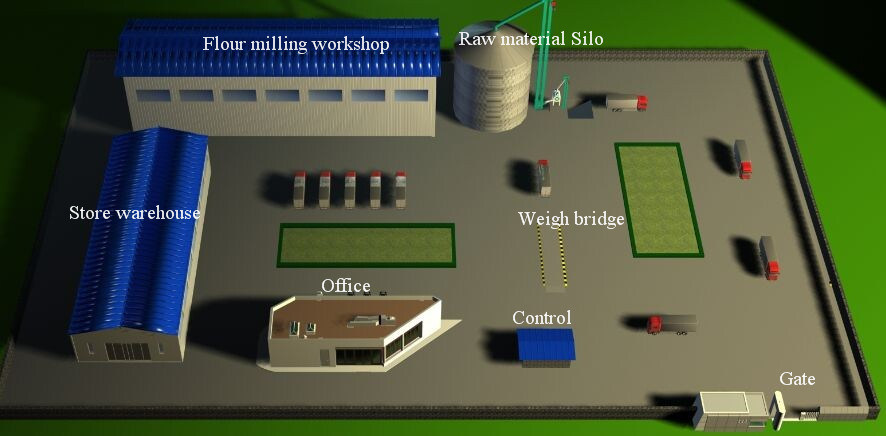

III. Factory area planning

Don't design the factory building hastily, and discuss with professional scientific research units to formulate a feasible factory construction plan. Including the division of living and production areas. The living area includes staff dormitories and green space construction. The production area includes the planning of office buildings and production plants. The design of office buildings must meet the needs of various functional departments, especially the needs of raw grain and finished product laboratories. In addition, the staff locker room and canteen must be taken into account. For the design outside the plant, if raw grain needs to be stored, the storage capacity and location of the silo must be planned. The plant includes the cleaning part, grinding part, flour making part, flour blending part, packaging part and finished product storage part.

IV. Process and equipment selection

Through the above investigation, actively discuss with professional design agencies to determine the process suitable for your own company. At the same time, according to the process, query the qualifications and reputation of various equipment professional manufacturers, and consult the equipment price through the manufacturer. Taking wheat flour milling as an example, it includes the following main equipment prices, storage equipment (silo), flat rotary screen, high-efficiency vibrating screen, wheat blender, milling machine, high square flat screen, powder purifier, powder blender, packaging scale and other auxiliary equipment such as conveying, magnetic separation, fan, etc., compare prices, so as to find equipment suitable for your own company.

5. Network application

With the development of society, network technology has been widely used. When building a factory, enterprises should consider establishing and improving their own quality network control from raw materials to finished products. Display various rules and regulations through the network, so that each functional department can clarify its responsibilities and strictly control the quality of each batch of products. Then improve the company's sales network, promote the company's products, and use the Internet to achieve the purpose of promotion.

#flourmill #maizemill #wheatmill