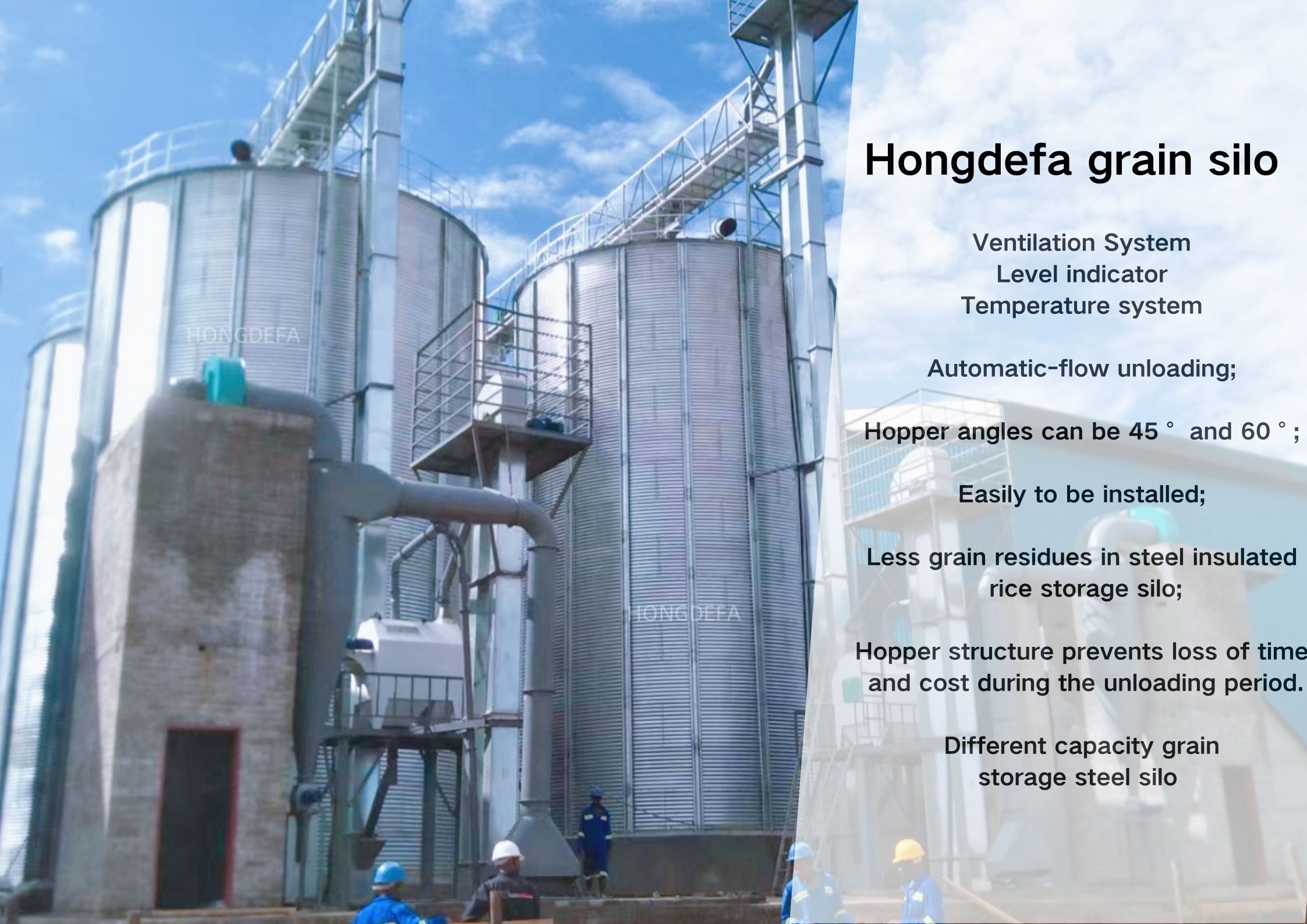

Hongdefa high quality wheat/corn/maize grain silo

A grain silo is a specialized type of storage silo designed specifically for the purpose of storing grain. These silos are commonly found on farms, in grain elevators, and at processing plants. They are constructed to keep the grain dry, preventing spoilage and maintaining its quality. Grain storage silos often have airtight seals to protect against pests and contaminants, and they may be equipped with temperature control systems to further preserve the grain. The design of these silos facilitates the efficient loading, unloading, and management of large quantities of grain, making them an essential component of the agricultural supply chain.

Grain silo description:

For the grain storage silo,we have different capacity from 100T to 10000T grain storage silo.

And we have different type silo for you to choose,like flat bottom silo,cone bottom silo.

For one set complete grain storage silo,should include:

1. Pre-cleaning system.

2. Drying system.

3. Level monitor, temperature controller, ventilation system.

4. Silo body including silo roof, silo body, silo bottom and other quxiliary.

The grain silo is mainly supply for big raw grain farm,seed company,milling factory and so on.

1. Capacity: 1000 Tons

2.Cubic: 1300M3

Flow sheet of 1000T grain silo

![]()

The structure introduction of grain silo:

1. Silo body:

The silo is made of high quality hot-galvanized steel plates which are rolled into corrugation and made into srandard connecting holes.These plares are connected by high-strength screw bolts.The silo plates' thickness distribution is set according to equal strength theory which makes the silo plates bear average stress.The vertical friction is supported in the silos.The connection holes are served with round galvanized steel washers and the connection holes are served with age-resistant and water-proof washers.The silo plates' interval is injected by water-proof daub belts that are for aviation special purpose.The silo is assisted with flat repairing doors,outside ladder,ladder guard rings.

2.Silo top:

The silo top adopts umbrella frame and the frame material is made of C model straight carbon steel. The ceiling is made of galvanized steel tile plates.The silo top served with natural ventilation windows,manhole,ladder,safety guards.

3.Cement cone/flat base:

When the silo capacity is comparatively big and its diameter is below 12m.Its base is generally made into cement cone base.Cement cone base is an inverted cone hopper case into frame with cement and concrete.It makes unloading stuff automaticlly.When the silo diameter is more than 12m,because the cone base height is too big,its base generally made into half-cone base or plat base.Half-cone base can't completely unload the stuff.Flat base silo needs to unload stuff at multi-parts or equipped with a spiral silo cleaner.Cement cone base has a mediate construction price,but has a long construction period.

![]()

The advantage of grain silo:

1.On reasonable structure is safe and reliable: silo for the keel and corrugated steel plate combines type steel structure,the overall strength,good stability,the use of deformation,the bin body all galvanized parts,the service life reaches gb.(25years)

2.Supporting system of complete:

1)with automatic temperature measuring system,

2)equippes with ventilation system,effectively prevent grain mildew

3)material system can display the state of silo inside,to realize the automatic display and control

4)according to user requirements can be equipped with drying and fumigation system

5)with import warehouse transportation equipment,grain cleaning equipment,realize the materials in and out of warehouse automation.

3.Standard for the installtion of safety of fast:

All materials standard parts,production,installation.Short construction period.Barn all connected by bolts,can be easily disassembled into parts,to achieve the overall demolition land reorganization.Convenient repair,local damage can be replaced.

4.Of advanced technology cost-effective:

With brick silo,Fang Shicang,has a short construction period,good anti-seismic performance,light weight,low cost,based on the comprehensive advantages of low cost.

Successful projects

We have installed many different capacities grain silo in different countries.

| Capacity | Country |

| 300T grain silo | Zimbabwe,Sir Lank,Angola,Malawi, |

| 500T grain silo | Zambia,Uganda,Angola,Kenya,Nigeria, |

| 1000T grain silo | Zambia,DR Congo,Zimbabwe,Angola,Nigeria,Uganda,Benin |

| 2000T grain silo | Tanzania,Zambia,Zimbabwe,Nigeria,DR Congo |

| 3000T grain silo | DR Congo,Zimbabwe,Zambia |

| 3500T grain silo | DR Congo,Zimbabwe |

![]()

1. 4*500T grain silo have installed in Nigeria

2. 3*3500T grain silo have installed in DR Congo

3. 5*3000T silo have installed in Zimbabwe

Sales and service network

We have professional presales service department and aftersales service department. And we have professional technique department will make the machine design based on client reuqest and local market.

Sales map:

We have sold many milling machines and grain silos to over 50 different countries,like Zambia,Uganda,Kenya,Zimbabwe,Malawi,Angola,Tanzania,Nigeria,Benin,India,Thailand,Egypt,Afghanistan and so on

Clients photo

Clients photo

![]()

We have two branch office and eight local agents in Africa

Two branch office: Zambia and Ethiopia

Eight local agents: Senegal,Nigeria,Ghana,DR Congo,South Africa,Zimbabwe,Kenya,Egypt

FAQ:

Q1.Are you a trading company or a manufacturer?

We are a professional manufacturer,we already have over 30 years experiences in flour mill market.

Q2.What is the payment method?

Normally we use T/T payment,30% payment as deposit,70% balance payment need to pay before shipping.

Q3.Who will install the grain silo please?

We have professional installation team,we will send our engineer to guide to install the grain silo.

![]()

About Us

Our company is a professional manufacture of maize mill machine and wheat flour mill machine,we provide high quality machine different capacity with different design according to client needs,with European technology,South Africa maize process,China wheat process,roll out unique and innovative wheat flour mill and maize mill plant.

And we also supply different capacities grain silo to different countries.

The head office of Shijiazhuang Hongdefa Machinery Co.,Ltd is located in Wumashan industrial area, Zanhuang County, Shijiazhuang City, 4hours driving From Beijing. Hongdefa has approximately 120 workers, a manufacturing factory 50000 square meters, and 5000 square meters of production workshop, 6000 square meters warehouses,1000 square meters of office space.

Why choose us

We are the professional manufacturer of maize milling plant and wheat milling machine. We are the real factory.

We use advanced process machine to process raw material of grain silo.

We have super technique team and sales team to do service for clients.

We have super technique team and sales team to do service for clients.

![]()

Certifications

We can do different certifications based on client request and local market.For example,

We can do COC for Kenya client,

We can do PC for Nigeria client and so on.

Installation service:

We have professional installation team to do the installation service for client.

After client's water and electricty is ready,we will arrange to send our engineer to guide to install the grain silo.

Contact us:

If you are interested in our grain silo,kindly please contact us freely.

Contact person: Wiwi Zhang

#silo #grainsilo #steelsilo #storagesilo